In today’s fast-paced industrial and logistics environments, optimizing material handling systems is essential. Pallet conveyors play a crucial role in streamlining operations, ensuring that heavy loads and bulky materials move efficiently through a facility. However, selecting the right type of pallet conveyor for your business can be challenging. This blog explores the different types of pallet conveyors available and helps you determine which one suits your specific needs.

Why Choose Pallet Conveyors?

Pallet conveyors are designed to handle and transport heavy loads with ease. They minimize manual labor, reduce operational costs, and increase productivity. Choosing the right type of pallet conveyor is critical to ensuring seamless integration with your existing systems and workflows.

Types of Pallet Conveyors

-

Gravity Pallet Conveyors

- How It Works: Uses gravity to move pallets along a sloped track.

- Best For: Facilities with limited automation or short-distance transport needs.

- Pros:

- Cost-effective and low maintenance.

- Energy-efficient as no power is required.

- Cons:

- Limited control over pallet movement.

- Unsuitable for inclines or declines with heavy loads.

-

Chain-Driven Pallet Conveyors

- How It Works: Uses a chain-driven mechanism to move pallets along a conveyor.

- Best For: Handling heavy-duty pallets and applications requiring consistent movement.

- Pros:

- Durable and ideal for tough environments.

- Handles high-weight capacities.

- Cons:

- Higher initial cost.

- Requires regular maintenance.

-

Roller Pallet Conveyors

- How It Works: Utilizes rollers powered by motors or gravity to move pallets.

- Best For: Warehouses with automated systems and high throughput.

- Pros:

- Suitable for a wide range of pallet sizes.

- Easy to integrate with other automation systems.

- Cons:

- May require additional safety features for worker protection.

-

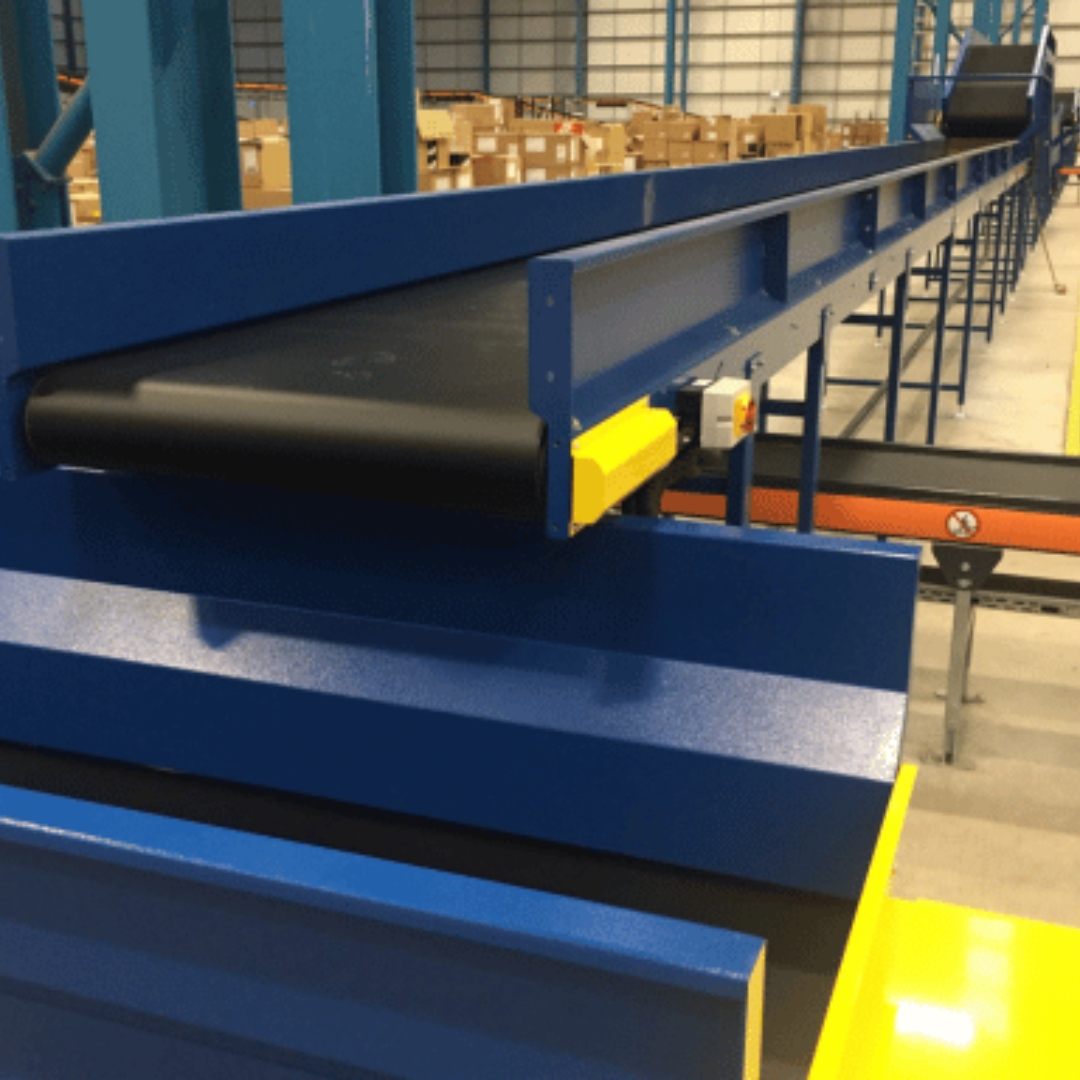

Belt-Driven Pallet Conveyors

- How It Works: Uses a belt to transport pallets, ensuring smooth and steady movement.

- Best For: Applications requiring gentle handling, such as fragile or irregularly shaped loads.

- Pros:

- Provides consistent movement.

- Reduces wear and tear on pallets.

- Cons:

- Limited to lighter loads compared to chain or roller systems.

- More prone to wear and maintenance needs.

-

Turntable Pallet Conveyors

- How It Works: Allows pallets to change direction or orientation while on the conveyor.

- Best For: Facilities requiring flexibility in pallet handling and layout optimization.

- Pros:

- Saves space in tight layouts.

- Reduces manual handling.

- Cons:

- Can be more expensive than straight conveyor systems.

-

Transfer Pallet Conveyors

- How It Works: Moves pallets from one conveyor line to another using transfer modules.

- Best For: Complex layouts with multiple lines of pallet movement.

- Pros:

- Versatile and customizable.

- Ensures efficient material flow.

- Cons:

- Higher installation costs.

Factors to Consider When Choosing a Pallet Conveyor

To find the right pallet conveyor for your business, consider the following:

- Load Requirements: Determine the weight and dimensions of the pallets you need to move.

- Speed and Throughput: Assess how fast you need the system to operate to meet your production goals.

- Space Availability: Evaluate the space in your facility and choose a conveyor system that fits seamlessly.

- Integration Needs: Consider how the conveyor will work with your existing equipment and systems.

- Budget: Weigh the upfront and maintenance costs against the system's long-term benefits.

Conclusion

Choosing the right type of pallet conveyor can significantly impact your business's operational efficiency and productivity. Whether you need a cost-effective gravity system or a fully automated chain-driven solution, understanding the strengths and limitations of each type will help you make an informed decision.

If you're unsure about which pallet conveyor is right for your business, consult with a trusted supplier or material handling expert. The right choice will not only streamline your operations but also pave the way for future growth and success.