In today’s fast-paced industrial world, efficiency is key. Companies are constantly looking for ways to improve productivity, reduce manual labor, and streamline operations. One of the unsung heroes of this mission is the pallet conveyor system. Whether in manufacturing, warehousing, or distribution, pallet conveyors play a crucial role in moving heavy goods with precision and speed.

What is a Pallet Conveyor?

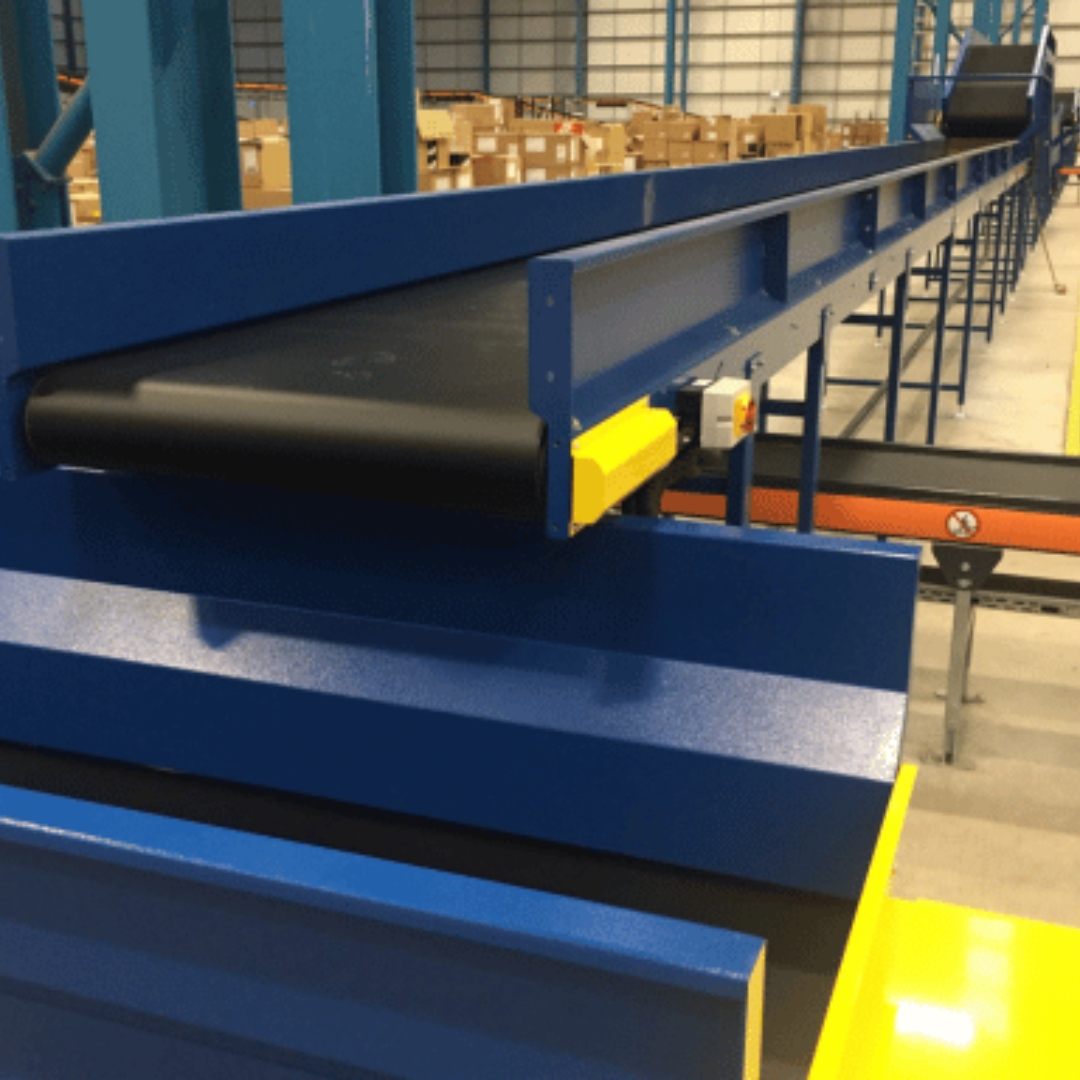

A pallet conveyor is a mechanical handling device designed to transport pallets — flat transport structures that carry goods — across a facility. Unlike standard conveyors meant for smaller items, pallet conveyors are built to handle heavy, bulky loads typically ranging from 500 to 2000 kilograms or more.

These systems use a combination of belts, rollers, or chains to move pallets smoothly from one point to another, ensuring minimal manual handling and reducing the risk of damage or injury.

Types of Pallet Conveyors

Depending on the specific needs of an operation, there are several types of pallet conveyors to choose from:

1. Chain-Driven Pallet Conveyors

These conveyors use heavy-duty chains to move pallets. They are ideal for very heavy loads and are commonly used in rugged environments like manufacturing plants.

2. Roller Pallet Conveyors

In this design, pallets move along rollers, either powered or gravity-fed. Powered roller conveyors are great for controlled movement, while gravity versions are ideal for simple, downhill transfers.

3. Belt-Driven Pallet Conveyors

These systems use a belt underneath the rollers to provide motion. They are often used when smooth, even motion is critical, or when pallets must be moved up or down inclines.

4. Turntable Pallet Conveyors

When the direction of pallet movement needs to change (such as 90° turns), turntable conveyors come into play. These systems rotate the pallet without the need for complex manual handling.

Key Benefits of Pallet Conveyors

✔️ Improved Efficiency

Pallet conveyors automate the movement of heavy loads, saving significant time and reducing bottlenecks in production and warehousing operations.

✔️ Enhanced Safety

By reducing manual handling, pallet conveyors help lower the risk of workplace injuries, protecting your workforce and lowering insurance costs.

✔️ Cost Savings

Though they require upfront investment, pallet conveyor systems significantly reduce labor costs over time, offering a solid return on investment.

✔️ Space Optimization

Pallet conveyors can be customized to fit your facility layout, including vertical lifts and stackers that maximize space usage.

✔️ Reliability and Durability

Built to withstand tough conditions, pallet conveyors are a long-lasting solution for industries dealing with heavy goods.

Applications of Pallet Conveyors

-

Manufacturing plants for moving raw materials or finished products

-

Warehouses and distribution centers for order fulfillment

-

Automotive industries for parts transportation

-

Food and beverage industries for bulk goods handling

-

Pharmaceutical sectors where clean and efficient movement of heavy batches is critical

Factors to Consider When Choosing a Pallet Conveyor

When selecting a pallet conveyor for your operations, consider:

-

Load Weight and Size: Ensure the system can handle your heaviest pallets.

-

Facility Layout: Choose between straight, curved, or multi-level conveyors based on your space.

-

Speed Requirements: Some operations require faster pallet movement than others.

-

Environmental Conditions: For example, cold storage facilities may need specially designed conveyors.

-

Budget: Balance initial investment with long-term savings and efficiency gains.

Conclusion

Pallet conveyors are a smart investment for any business handling heavy loads. By improving efficiency, enhancing safety, and reducing costs, they become an integral part of a well-oiled supply chain. Whether you’re upgrading an existing system or setting up a new facility, a tailored pallet conveyor solution could be the key to your operational success.