In today's fast-paced industrial landscape, rolling conveyor systems have become an essential component of efficient material handling. Whether in manufacturing, packaging, or distribution, businesses across the UK are turning to trusted conveyor manufacturers to streamline operations, reduce manual labour, and improve productivity. This blog takes a closer look at what makes rolling conveyor systems vital and highlights why the UK is a hub for world-class manufacturers in this field.

What Are Rolling Conveyor Systems?

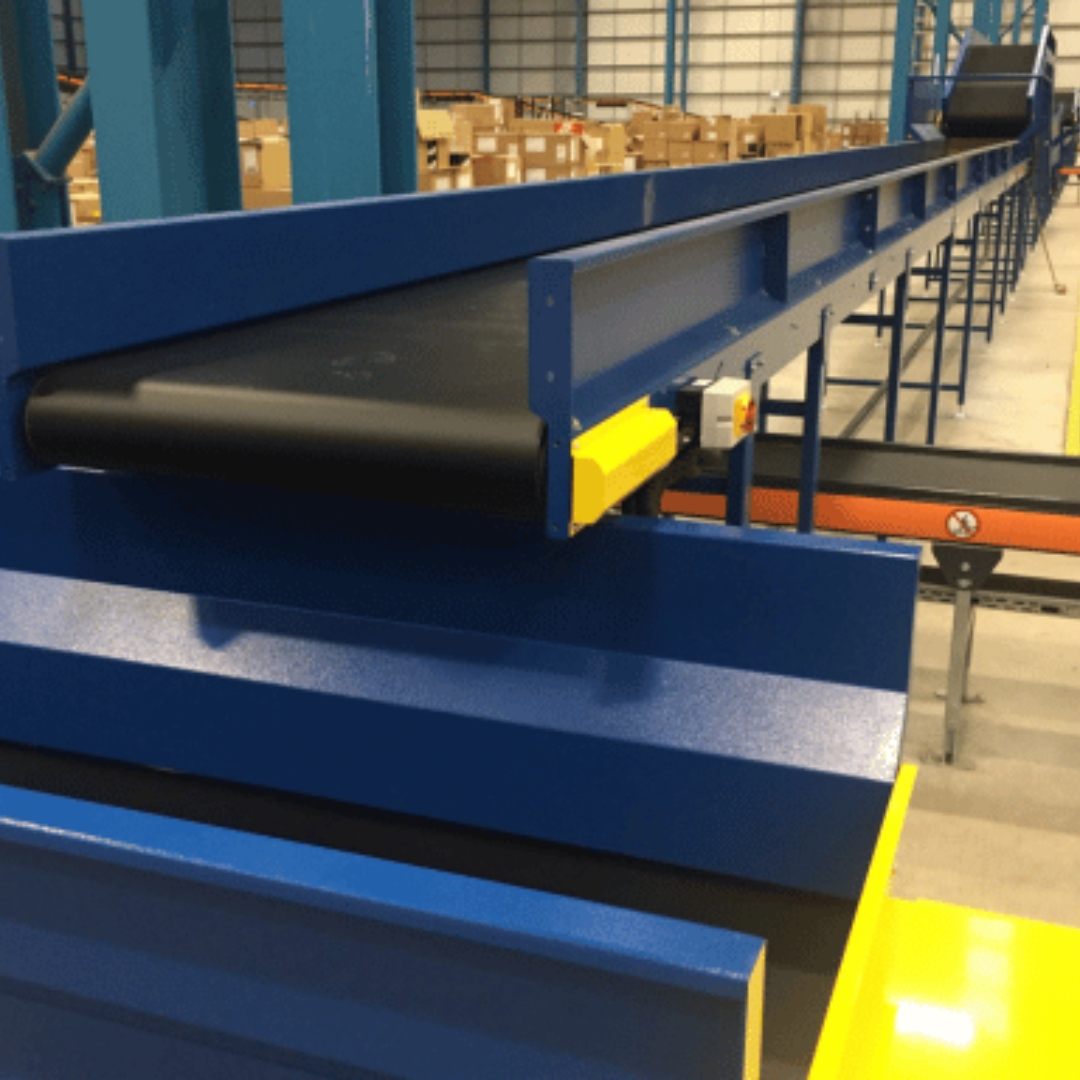

Rolling conveyor systems, often referred to as gravity or powered roller conveyors, use cylindrical rollers to transport items from one point to another. Their design allows for the smooth movement of boxes, pallets, and heavy loads with minimal effort. Common in warehouses, assembly lines, and logistics centres, these systems are praised for their durability, modularity, and ease of integration.

Why Choose UK-Based Rolling Conveyor Manufacturers?

The UK’s engineering sector is known for its innovation and high-quality standards. Manufacturers in the UK offer several advantages:

-

✅ Advanced Technology: Many UK manufacturers utilise cutting-edge automation, IoT integration, and smart controls in their conveyor solutions.

-

✅ Customisation: From bespoke designs to modular systems, UK companies can tailor conveyor solutions to fit specific industry needs.

-

✅ Compliance & Safety: British manufacturers adhere strictly to ISO and CE standards, ensuring safety and legal compliance.

-

✅ Sustainability: There's a growing focus on energy-efficient and low-maintenance conveyor designs, supporting environmental goals.

Leading Industries Using Rolling Conveyor Systems

Rolling conveyors are versatile and support a wide range of industries in the UK, including:

-

E-commerce & Fulfilment Centres: Streamlining order picking and packing processes.

-

Food & Beverage: Ensuring hygienic and efficient movement in processing lines.

-

Automotive: Supporting assembly lines with heavy-duty roller conveyors.

-

Pharmaceutical: Enhancing accuracy and compliance in sensitive environments.

Key Features to Look for in a Manufacturer

When choosing a rolling conveyor system manufacturer, consider the following:

-

Experience & Reputation: Look for companies with proven expertise in industrial automation and a solid track record.

-

Engineering Support: Top manufacturers provide consultation, design, installation, and maintenance support.

-

Material Quality: Stainless steel rollers, galvanised frames, and heavy-duty bearings ensure long life.

-

Innovation: Look for smart conveyors with automated sensors, programmable controls, and AI-driven logistics optimisation.

Trusted Rolling Conveyor Manufacturers in the UK

Several UK-based manufacturers have earned a reputation for delivering excellence:

-

Conveyor Systems Ltd – Offering tailored conveyor solutions with a focus on retail and warehouse applications.

-

L.A.C. Conveyors & Automation – Known for advanced automation and intelligent conveyor design.

-

Monk Conveyors – Specialists in modular conveyors for a wide range of sectors including pharmaceutical and automotive.

-

Excel Conveyors – Providing cost-effective yet high-performance solutions for SMEs.

Final Thoughts: Investing in the Right Conveyor Partner

Choosing the right rolling conveyor system manufacturer in the UK can transform your operational efficiency. It’s not just about buying equipment—it’s about investing in future-ready logistics infrastructure. From initial design to installation and aftercare, a reliable manufacturer will partner with you to optimise every aspect of material handling.

Frequently Asked Questions

Q1: Are rolling conveyor systems suitable for heavy-duty applications?

Yes, heavy-duty rolling conveyors are designed to handle loads exceeding several hundred kilograms, ideal for manufacturing and pallet handling.

Q2: Can these systems be integrated with automation software?

Absolutely. Many UK manufacturers offer smart integration with WMS, barcode scanners, and robotics for seamless operations.

Q3: What maintenance do rolling conveyors require?

Minimal maintenance is needed—periodic roller checks, belt alignment (for powered systems), and lubrication keep systems running smoothly.