Introduction

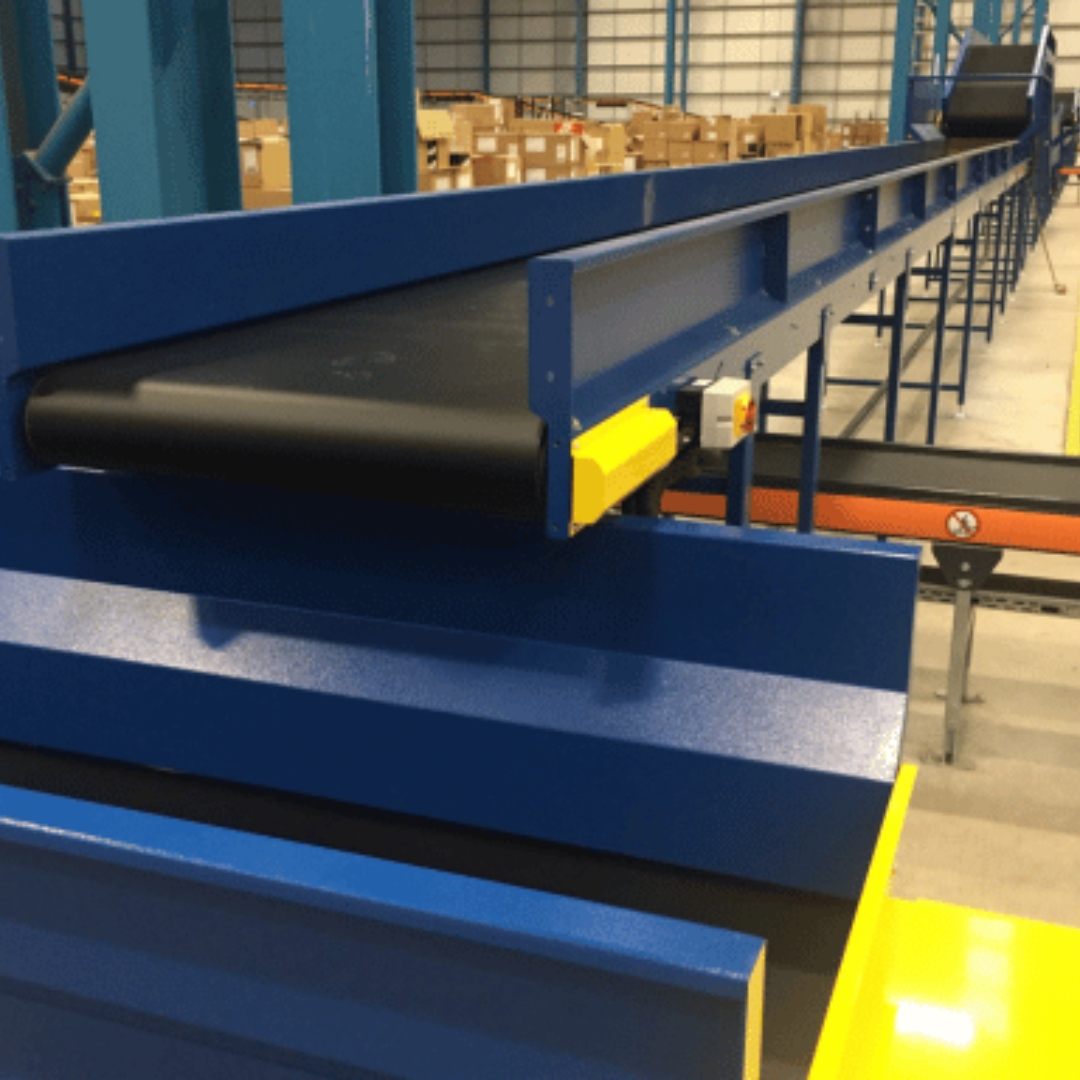

In today’s fast-paced industrial world, efficiency is everything. Whether it's warehousing, packaging, or assembly lines, rolling conveyor systems play a vital role in streamlining operations and improving productivity. The UK is home to some of the most reputable manufacturers of rolling conveyor systems, known for their engineering excellence, innovation, and compliance with high safety standards. In this blog, we’ll explore what makes UK manufacturers stand out, key features to look for in a rolling conveyor system, and top sectors that benefit from this essential material handling equipment.

Why Choose Rolling Conveyor Systems?

Rolling conveyor systems, also known as roller conveyors, are used to move products efficiently with minimal effort. They are ideal for transporting goods across long distances in manufacturing plants, warehouses, distribution centres, and airports. Key benefits include:

-

Improved workflow efficiency

-

Reduced manual handling and labour costs

-

Customisable configurations for different products and spaces

-

Durability and low maintenance

What Sets UK Manufacturers Apart?

The UK manufacturing sector is recognised globally for its adherence to high-quality standards, custom engineering solutions, and customer support. Leading UK-based rolling conveyor system manufacturers typically offer:

-

Bespoke system design tailored to specific business needs

-

High-grade materials including stainless steel, aluminium, and zinc-coated rollers

-

Integration with automated systems, sensors, and software

-

CE and ISO certifications for safety and quality assurance

-

Responsive customer service and reliable after-sales support

Key Features to Consider When Choosing a Rolling Conveyor System

-

Load Capacity: Ensure the system can handle the weight of your products consistently.

-

Roller Material: Stainless steel for hygiene and durability; PVC for lighter items.

-

Adjustability: Telescopic conveyors and height-adjustable designs add flexibility.

-

Modularity: Scalable systems allow for easy expansion as your business grows.

-

Drive Mechanism: Gravity rollers for simplicity or powered rollers for automation.

Industries That Rely on Rolling Conveyor Systems

-

Logistics & Distribution: For fast, efficient sorting and packaging of goods.

-

Food & Beverage: Hygienic designs with easy-to-clean materials.

-

Manufacturing: Assembly lines with integrated automation.

-

E-commerce & Retail: Fulfilment centres that require high-speed processing.

-

Automotive: Transport of components across assembly stations.

Top UK Rolling Conveyor System Manufacturers

Here are some of the leading names in the UK known for their expertise:

-

Conveyor Systems Ltd (CSL) – Based in West Sussex, offers bespoke solutions.

-

L.A.C. Conveyors & Automation – Known for end-to-end turnkey systems.

-

Amber Industries – Specialises in gravity and powered roller conveyors.

-

Daifuku Logan – Focuses on airport baggage and industrial conveyor systems.

-

Coveya Ltd – Offers rapid deployment conveyors for hire and purchase.

Note: Always verify certifications and customer reviews before finalizing a supplier.

Final Thoughts

Investing in a high-quality rolling conveyor system can revolutionise your operations by improving speed, safety, and efficiency. With a range of innovative manufacturers in the UK, businesses can find tailor-made conveyor solutions to suit their unique needs. From robust construction to cutting-edge automation, the UK market is well-equipped to deliver world-class conveyor technology.