Introduction

In today's fast-paced manufacturing and logistics industries, efficiency and accuracy are everything. Whether you're labeling food packaging, pharmaceuticals, or shipping boxes, precision matters—not only for compliance but also for traceability and customer satisfaction. That’s where Print & Apply Labeling Systems come into play.

These advanced systems seamlessly combine printing and labeling processes into a single automated solution, revolutionizing how businesses handle product identification.

What Are Print & Apply Labeling Systems?

Print & Apply Labeling Systems are automated machines that print barcodes, batch numbers, expiration dates, or product information and immediately apply the label onto the product or packaging. Unlike traditional pre-printed labels, these systems offer on-demand labeling, which saves time and reduces waste.

Key Benefits of Print & Apply Labeling Systems

-

Real-Time Customization

Labels can be printed with dynamic data in real time, enabling customization for each individual product, pallet, or case. -

Increased Efficiency

With integrated printing and application, businesses save time and labor, reducing manual errors and increasing throughput. -

Enhanced Accuracy

Automated systems ensure labels are applied precisely and consistently, which is critical for barcode scanning and regulatory compliance. -

Cost Savings

Printing labels on demand minimizes inventory requirements for pre-printed labels and reduces waste due to label obsolescence. -

Improved Traceability

Vital for industries like food, pharma, and automotive, where accurate tracking through barcodes or QR codes is essential.

Applications Across Industries

-

Manufacturing: Apply product IDs, safety info, or compliance labels directly on products or cartons.

-

Food & Beverage: Label expiry dates, ingredients, and batch codes in fast-moving production lines.

-

Pharmaceutical: Ensure 100% traceability with serialized labels and tamper-evident seals.

-

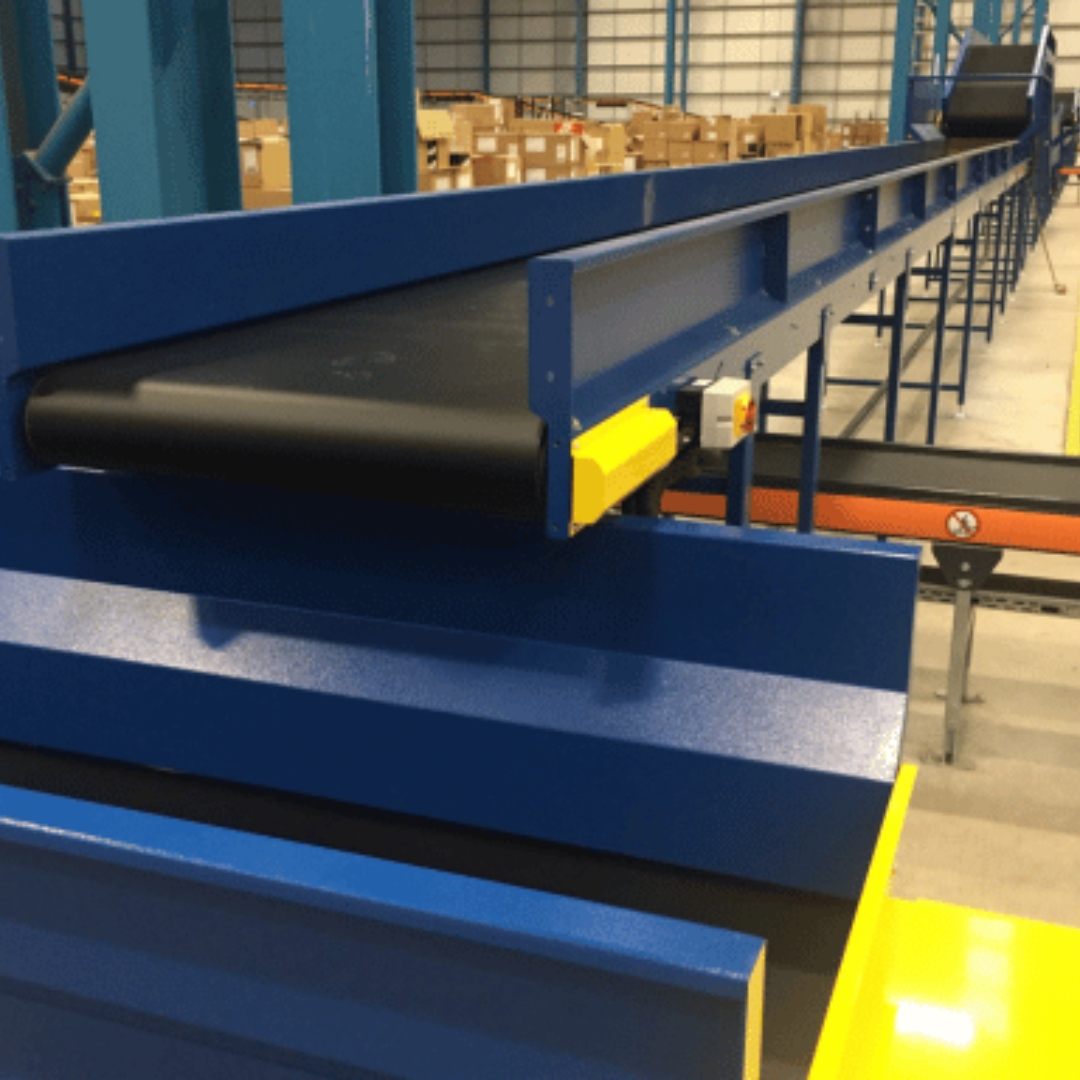

Logistics & Warehousing: Label pallets, packages, or shipping boxes with accurate data for tracking and automation.

Choosing the Right Print & Apply Labeling System

When selecting a system, consider:

-

Speed requirements (items per minute)

-

Product size and shape

-

Labeling location (top, side, bottom, corner-wrap)

-

Connectivity with ERP/WMS systems

-

Printer technology (thermal transfer, direct thermal)

Leading manufacturers often offer modular systems that can grow with your business, allowing flexibility in configuration and future upgrades.

Conclusion

In an era where accuracy, speed, and compliance are non-negotiable, Print & Apply Labeling Systems stand out as an indispensable solution for modern operations. By automating the labeling process and ensuring every product is marked correctly, companies can improve efficiency, reduce costs, and elevate their supply chain visibility.

Investing in a print & apply labeling system isn’t just about automation—it’s about building a smarter, more agile business.