In today’s fast-paced industrial landscape, efficiency is not just an advantage—it’s a necessity. From manufacturing and warehousing to distribution and logistics, companies are constantly seeking smarter, faster, and more reliable ways to move goods. At the heart of this logistical evolution lies an unsung hero: the pallet conveyor.

What Is a Pallet Conveyor?

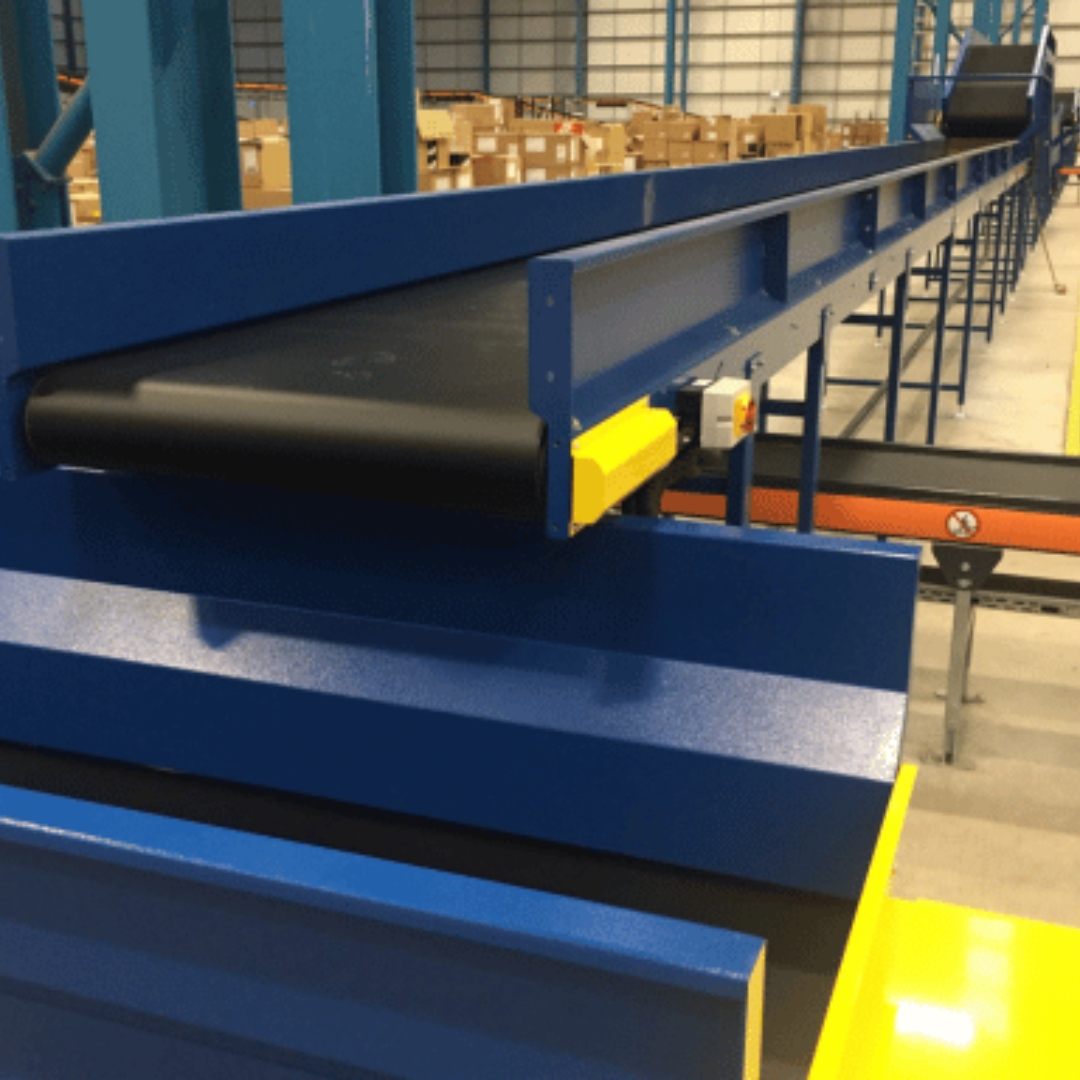

A pallet conveyor is a mechanical handling system designed to transport pallets—flat transport structures that support goods in a stable fashion—for easy movement through various stages of production or distribution. Unlike manual handling or traditional forklifts, pallet conveyors provide a streamlined, automated method of pallet movement that reduces labor costs and enhances productivity.

Why Industries Are Choosing Pallet Conveyors

1. Increased Efficiency

By automating the movement of heavy loads, pallet conveyors significantly cut down handling time. This not only speeds up operations but also minimizes downtime caused by human error or fatigue.

2. Improved Safety

Manual pallet handling can pose serious safety risks. Pallet conveyors eliminate the need for constant forklift traffic, reducing the chance of workplace accidents and injuries.

3. Consistent Flow of Goods

In industries where timing is critical—such as food and beverage, automotive, and pharmaceuticals—pallet conveyors ensure a continuous, consistent flow of products from one point to another.

4. Custom Solutions for Every Need

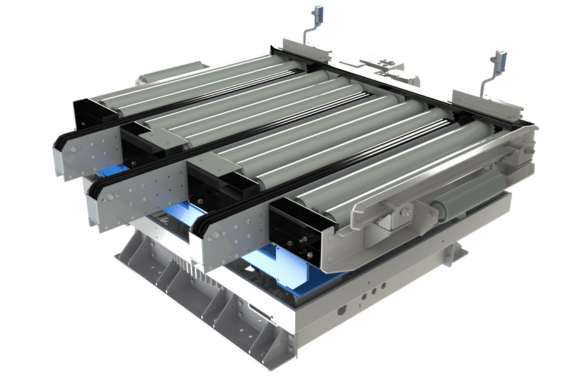

Modern pallet conveyor systems are highly customizable. From chain-driven to roller-based systems, manufacturers can design conveyors tailored to the weight, size, and fragility of the materials being transported.

Innovative Features Setting Top Manufacturers Apart

As a leading pallet conveyor manufacturer, we understand the growing demands of modern logistics. Here are some of the cutting-edge features we integrate into our systems:

-

Heavy-Duty Construction: Built to endure the most demanding environments.

-

Modular Design: Enables easy expansion or reconfiguration as operational needs evolve.

-

Smart Sensors & Controls: Incorporate automation and IoT capabilities for smarter material handling.

-

Low Maintenance Design: Engineered for reliability with minimal downtime.

Applications Across Multiple Industries

Pallet conveyors are used in a variety of sectors:

-

Automotive: For moving heavy engine parts and assemblies.

-

Retail & E-Commerce: To manage high volumes of packaged goods efficiently.

-

Pharmaceutical: Where hygiene and precise logistics are critical.

-

Food & Beverage: For the smooth movement of packaged and palletized goods under strict safety standards.

Choosing the Right Pallet Conveyor Manufacturer

When selecting a manufacturer, quality, customization, and after-sales support are key. A reliable partner will not only provide a superior product but also help you integrate it seamlessly into your current operations, ensuring maximum ROI.

At orionmis, we pride ourselves on delivering robust, efficient, and tailor-made pallet conveyor systems. Whether you're upgrading your current facility or building a new logistics hub, our engineering team works closely with you to understand your challenges and offer innovative solutions that drive growth.

Final Thoughts

Pallet conveyors are not just equipment—they are strategic assets in your supply chain. Investing in a high-quality, well-designed pallet conveyor system is a step toward safer workplaces, faster processes, and more scalable operations. As industries continue to evolve, the pallet conveyor stands firm as a cornerstone of intelligent material handling.

Ready to transform your operations? Contact us today to discover how our pallet conveyor systems can power up your productivity.