In today’s fast-paced supply chain environment, efficiency, speed, and accuracy are paramount. As e-commerce and global trade continue to grow, businesses are increasingly turning to automated warehouse systems to gain a competitive edge. These systems are transforming traditional warehousing through advanced robotics, AI, and real-time data processing.

What Are Automated Warehouse Systems?

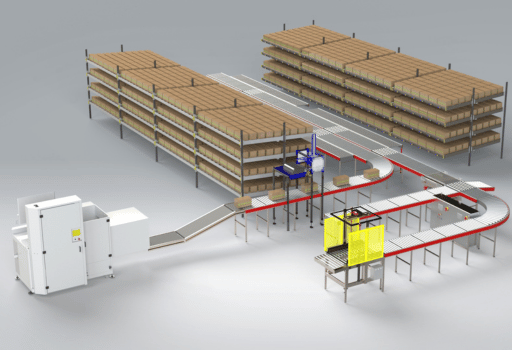

Automated warehouse systems refer to the use of machines, software, and control systems to perform tasks that were traditionally done manually. These tasks include storing, retrieving, sorting, and transporting goods within a warehouse. Some common technologies involved are:

-

Automated Storage and Retrieval Systems (AS/RS)

-

Robotic picking and sorting

-

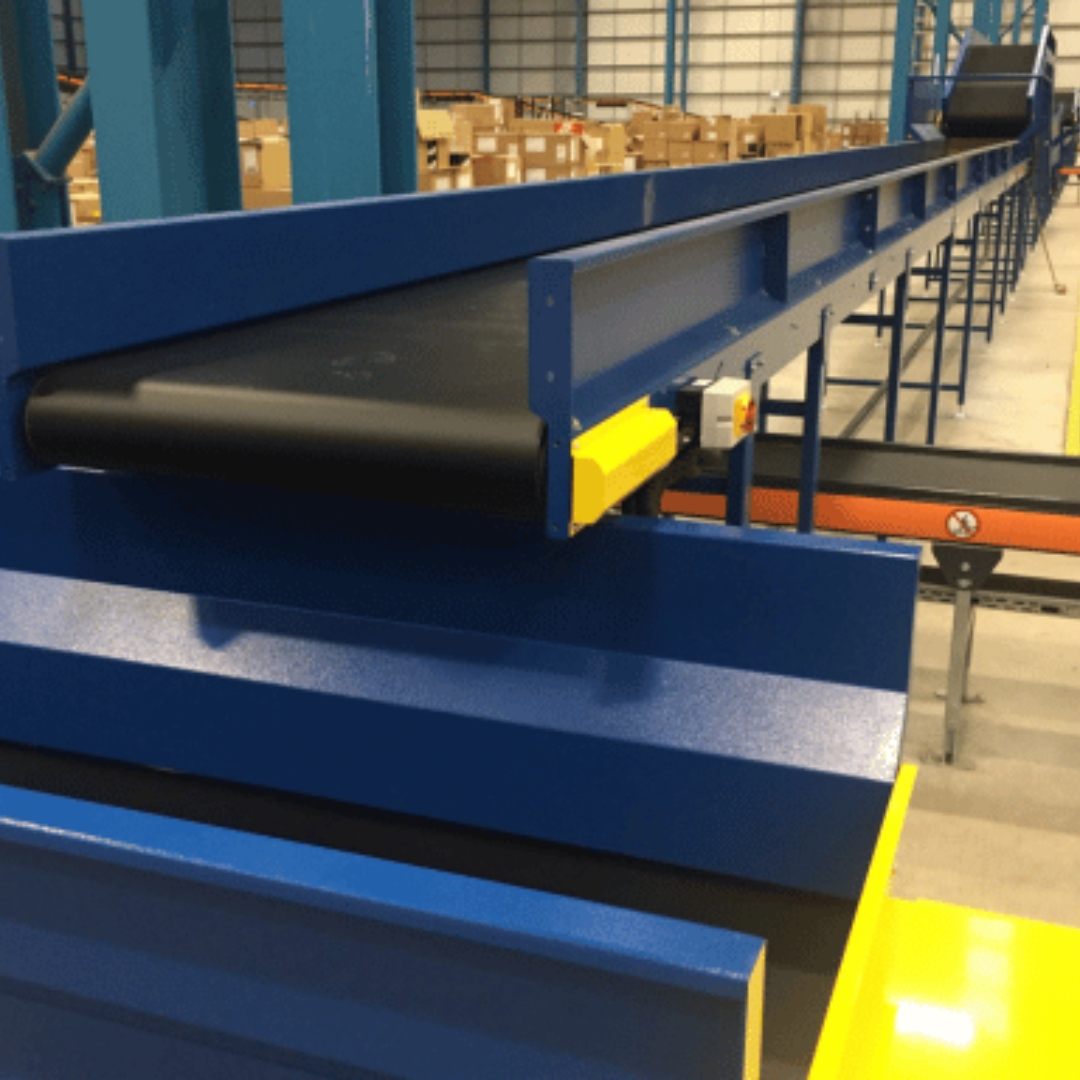

Conveyor systems

-

Warehouse Management Systems (WMS)

-

Drones and AGVs (Automated Guided Vehicles)

Key Benefits of Automation in Warehousing

-

Increased Efficiency and Speed

Automated systems operate around the clock, dramatically reducing the time required to move goods from storage to dispatch. This results in faster order fulfillment and improved customer satisfaction. -

Reduced Operational Costs

Although the initial investment in automation can be high, it leads to significant savings over time by minimizing labor costs, reducing errors, and lowering energy consumption. -

Enhanced Accuracy and Inventory Management

Integrated WMS and real-time tracking reduce the likelihood of human errors, ensuring that inventory counts are accurate and product locations are easily traceable. -

Scalability

Automation allows businesses to scale their operations without a proportional increase in labor costs. Systems can be upgraded or expanded as demand grows. -

Improved Safety

Reducing human involvement in potentially hazardous tasks (e.g., lifting heavy loads, operating forklifts) minimizes the risk of workplace injuries.

Real-World Applications

-

E-commerce Giants like Amazon use high-tech robotic systems to pick, pack, and ship products quickly.

-

Pharmaceutical companies rely on automated systems for precision and compliance with strict storage conditions.

-

Retail chains use automated distribution centers to manage massive inventories and ensure timely delivery to stores.

Is Automation Right for Your Warehouse?

Before investing in automation, businesses should consider:

-

The size and volume of their operations

-

The complexity of their supply chain

-

Current and projected growth

-

Return on investment (ROI) timelines

Partnering with experienced automation providers can help tailor solutions to specific needs and ensure seamless integration.

The Future of Warehousing is Automated

With advances in AI, machine learning, and robotics, automated warehouse systems will only become more intelligent and adaptable. Whether it’s predictive maintenance, autonomous decision-making, or warehouse digital twins, the future is bright — and fast.

Conclusion

Automated warehouse systems are not just a trend — they’re the future of efficient, scalable, and reliable supply chain operations. By embracing automation, businesses can not only improve productivity but also enhance accuracy, safety, and customer satisfaction.