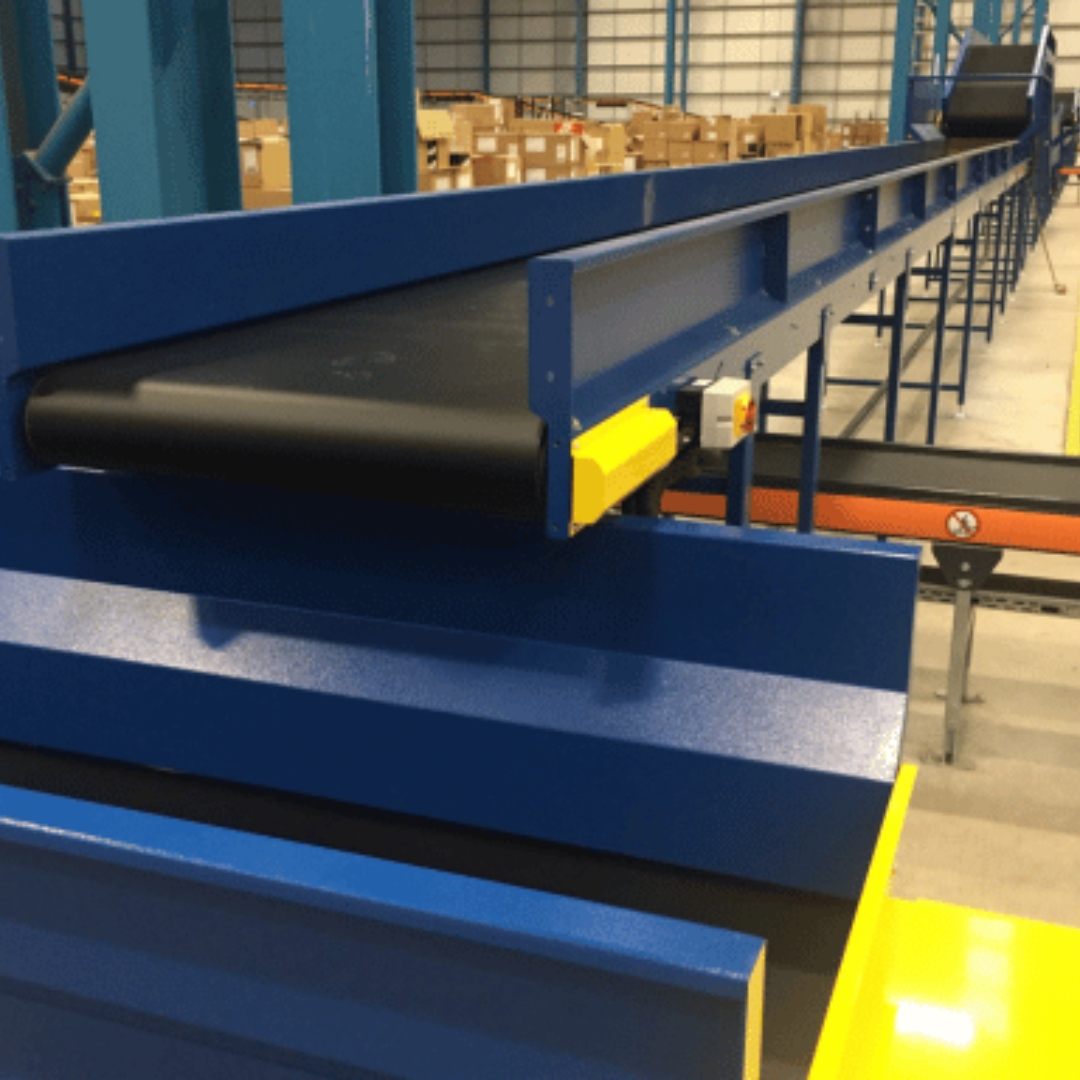

In today's fast-paced industrial world, efficient material handling systems are essential for smooth operations. Pallet conveyors play a crucial role in transporting heavy goods and materials in warehouses, manufacturing plants, and distribution centers. Whether you are moving raw materials or finished goods, pallet conveyors offer a reliable and automated solution to streamline your workflow.

What is a Pallet Conveyor?

A pallet conveyor is a type of material handling equipment designed to move pallets — flat transport structures that support goods in a stable manner while being lifted. These conveyors help in automating the movement of heavy and bulk products, reducing manual labor, and improving operational efficiency.

Key Benefits of Using Pallet Conveyors

1. Increased Efficiency and Productivity

Pallet conveyors reduce the need for manual lifting and moving, speeding up operations and increasing throughput in warehouses and factories.

2. Enhanced Safety

By minimizing the need for forklifts and manual handling, pallet conveyors help in reducing workplace injuries and accidents.

3. Cost-Effective Solution

Automating material handling processes reduces labor costs and minimizes product damage, offering long-term cost savings.

4. Flexible and Scalable

Pallet conveyor systems can be customized and scaled according to business needs, whether for small warehouses or large manufacturing units.

5. Optimized Space Utilization

Pallet conveyors allow better organization of goods, optimizing floor space and improving inventory management.

Types of Pallet Conveyors

1. Roller Pallet Conveyors

Equipped with heavy-duty rollers, these conveyors are ideal for moving standardized pallets smoothly. They can be motorized or gravity-fed, depending on operational needs.

2. Chain Pallet Conveyors

Chain conveyors use steel chains to move pallets and are perfect for handling heavier loads and rugged environments, such as automotive or steel industries.

3. Turntable Pallet Conveyors

Turntables are integrated into conveyor lines to rotate pallets, allowing easy change in direction without manual intervention.

4. Transfer Pallet Conveyors

These are designed to move pallets from one conveyor line to another, ensuring seamless transfer and routing.

5. Vertical Pallet Conveyors (Pallet Lifts)

Used to move pallets between different floor levels, vertical conveyors are essential in multi-level storage facilities.

Common Applications of Pallet Conveyors

- Warehousing and Distribution Centers: For transporting and sorting goods for dispatch.

- Manufacturing Units: For moving raw materials and finished products along production lines.

- Food and Beverage Industry: For safely transporting packaged goods.

- Automotive Industry: For moving heavy components and assemblies.

- Pharmaceuticals and Chemicals: For handling sensitive or hazardous materials safely and efficiently.

Choosing the Right Pallet Conveyor for Your Business

When selecting a pallet conveyor, consider the following factors:

- Load capacity requirements

- Type and size of pallets

- Operational environment (temperature, humidity, exposure to chemicals)

- Space availability

- Level of automation needed

Working with an expert pallet conveyor manufacturer or supplier can help you design a customized system that fits your operational needs perfectly.

Conclusion

Investing in a pallet conveyor system is a smart move for businesses aiming to improve efficiency, safety, and productivity. With various types available, pallet conveyors can handle a wide range of materials, making them a versatile solution for multiple industries.

If you are looking to upgrade your material handling system or install a new pallet conveyor line, contact us today for expert guidance and solutions tailored to your needs!