Boost Efficiency and Throughput with Powered Roller Conveyor Systems

Introduction

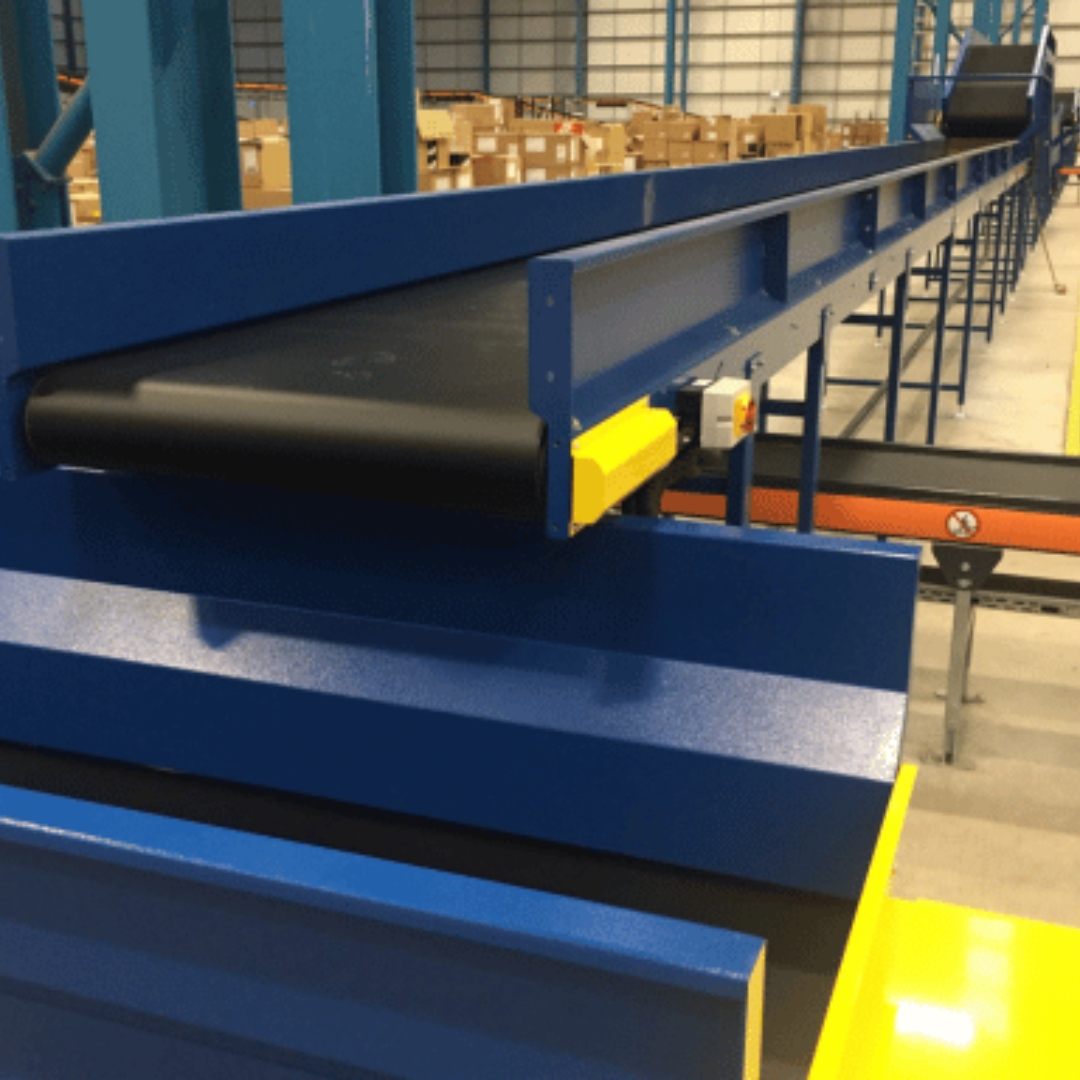

In today's fast-paced industrial and logistics environments, efficiency and automation are no longer optional—they’re essential. One of the most effective ways to streamline material handling and improve throughput is with a powered roller conveyor system. Whether in a warehouse, distribution center, or manufacturing facility, powered roller conveyors provide seamless, automated movement of goods with minimal manual intervention.

In this blog, we’ll explore what powered roller conveyor systems are, how they work, their key benefits, and the industries that can benefit the most from their implementation.

What Is a Powered Roller Conveyor System?

A powered roller conveyor uses motors to drive rollers and move items along the conveyor line. Unlike gravity conveyors, which rely on slope and gravity, powered systems are ideal for controlled and efficient movement of goods, especially over long distances or around curves and inclines.

They come in various configurations—line shaft, belt-driven, chain-driven, and motorized roller (MDR)—each suited to different applications depending on load size, speed, and operational environment.

Key Features of Powered Roller Conveyors

Benefits of Powered Roller Conveyor Systems

1. Increased Throughput

Automated movement of goods minimizes delays and improves flow, resulting in higher productivity and faster order fulfillment.

2. Improved Safety

Reduces manual handling, lowering the risk of workplace injuries. Operators can focus on supervision rather than physical transport.

3. Energy Efficiency

Many modern systems use energy-efficient motorized rollers (MDRs) that consume less power and operate only when items are detected on the rollers.

4. Low Downtime

Robust design and smart diagnostics reduce unexpected breakdowns and enable easy maintenance.

5. Scalability

From small operations to large warehouses, powered roller conveyors can scale to meet growing demands.

Common Applications

Is a Powered Roller Conveyor Right for Your Business?

If your operations involve frequent, repetitive movement of items—especially in high volumes—a powered roller conveyor system can dramatically enhance efficiency. It's also ideal if you're planning to integrate automation or robotics into your material handling strategy.

Conclusion

As industries continue to adopt smart technologies, the demand for reliable, scalable, and efficient conveyor systems will only increase. Powered roller conveyors are a smart investment for businesses seeking to optimize their logistics, reduce manual labor, and future-proof their operations.

Whether you’re upgrading your facility or designing a new one, powered roller conveyors can be a game-changer.