In today's fast-paced manufacturing and logistics environments, efficiency is paramount. One crucial aspect that often determines the smooth flow of operations is the labeling process. Enter the Print & Apply Labeling Systems—a game-changing solution designed to streamline operations, reduce errors, and boost productivity. This blog will delve into what these systems are, how they work, and why they are indispensable in modern manufacturing.

What Are Print & Apply Labeling Systems?

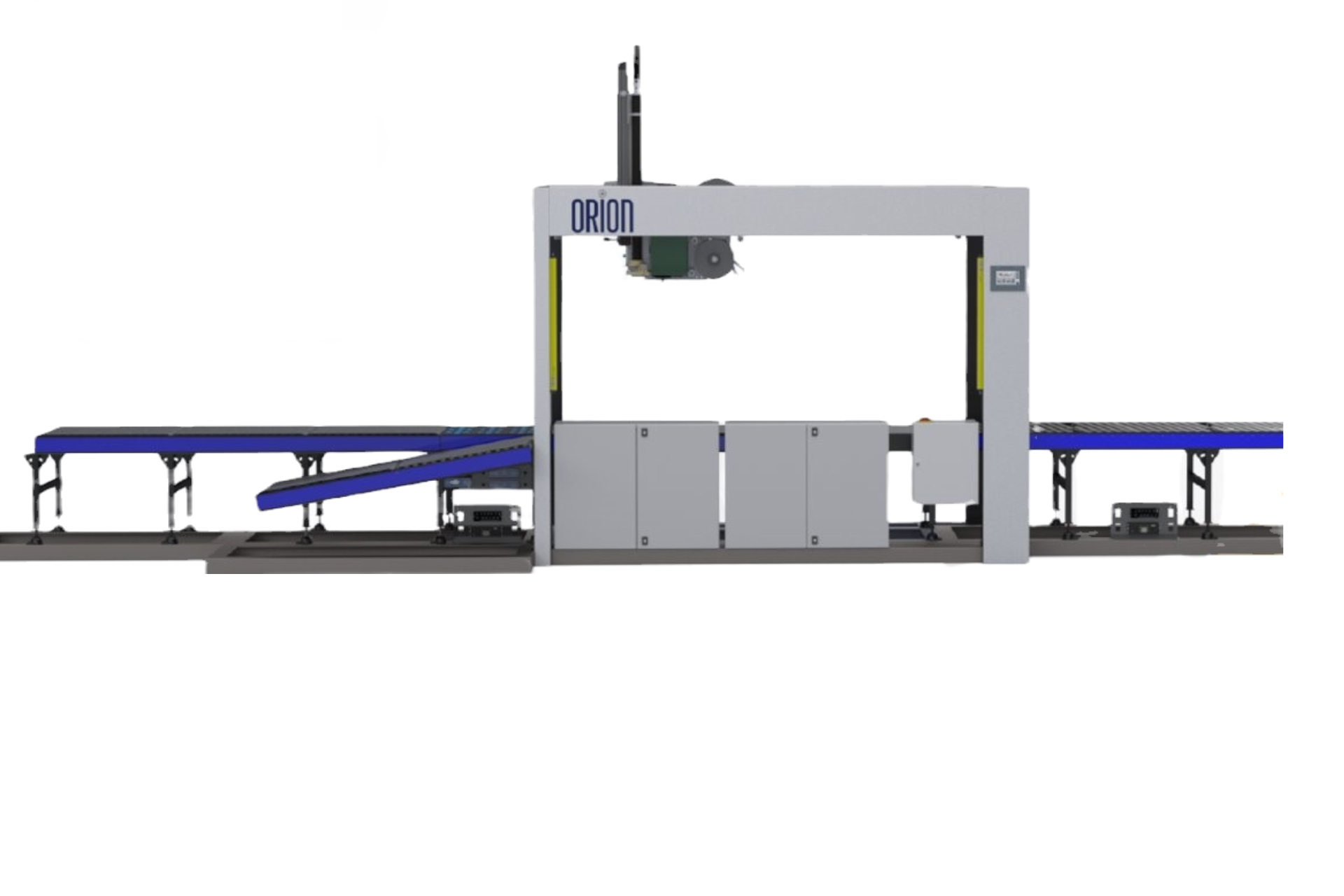

Print & Apply Labeling Systems are automated solutions used to print and apply labels on products, packaging, or pallets in real-time. Unlike traditional methods where labels are pre-printed and manually applied, these systems combine the printing and application processes into one seamless operation. This automation ensures that labels are accurate, legible, and placed correctly, reducing the risk of human error.

How Do Print & Apply Labeling Systems Work?

-

Data Input: The system receives data, such as product information, batch numbers, or barcodes, from a central database or an ERP system.

-

Label Printing: The system prints the label with the required information using advanced thermal transfer or direct thermal printing technology. This ensures that the print quality is high, and the label is durable enough to withstand various environmental conditions.

-

Label Application: Once printed, the label is immediately applied to the product, package, or pallet using a robotic arm or a pneumatic applicator. The system can apply labels in various orientations, such as top, side, or corner-wrap, depending on the product's shape and size.

-

Verification: Some systems come equipped with verification tools that scan the label to ensure accuracy before the product moves down the line. If a label is incorrect or unreadable, the system can alert operators or automatically reject the product for re-labeling.

Benefits of Print & Apply Labeling Systems

-

Increased Efficiency: By automating the labeling process, these systems significantly reduce the time it takes to label products, allowing for faster production lines and quicker order fulfillment.

-

Cost Savings: Automation reduces the need for manual labor, which can lower operational costs. Additionally, the accuracy of automated labeling reduces waste from mislabeled products or packaging.

-

Flexibility: Print & Apply systems can handle a wide range of label sizes, shapes, and materials, making them suitable for various industries, from food and beverage to pharmaceuticals and logistics.

-

Enhanced Accuracy: Automated systems eliminate human errors, ensuring that every label is correctly printed and applied, which is especially crucial for industries with strict labeling regulations.

-

Traceability: With the ability to print variable data, these systems enhance product traceability, which is vital for quality control, recalls, and compliance with industry standards.

Applications of Print & Apply Labeling Systems

- Food & Beverage: Ensuring that products are labeled with the correct nutritional information, expiration dates, and batch numbers.

- Pharmaceuticals: Applying labels that include barcodes, batch numbers, and expiration dates to ensure compliance with regulatory requirements.

- Logistics & Warehousing: Labeling pallets and packages with shipping information, barcodes, and RFID tags for efficient tracking and inventory management.

- Manufacturing: Applying labels with part numbers, serial numbers, and other identification information to components and finished goods.

Choosing the Right Print & Apply Labeling System

When selecting a Print & Apply Labeling System, consider the following factors:

- Production Speed: Ensure the system can keep up with your production line's speed without causing bottlenecks.

- Labeling Requirements: Choose a system that can handle the size, shape, and material of the labels your products require.

- Integration: The system should easily integrate with your existing production line and software systems.

- Support and Maintenance: Opt for a system from a reputable manufacturer that offers robust support and maintenance services.

Conclusion

In an era where efficiency and accuracy are key to staying competitive, Print & Apply Labeling Systems offer a powerful solution for manufacturers and logistics companies. By automating the labeling process, these systems not only improve operational efficiency but also ensure compliance with industry standards, making them an indispensable tool in modern production and distribution environments.