When selecting a print-apply labeling system, several key features can significantly enhance efficiency, accuracy, and adaptability in your labeling processes. Here are the essential elements to consider:

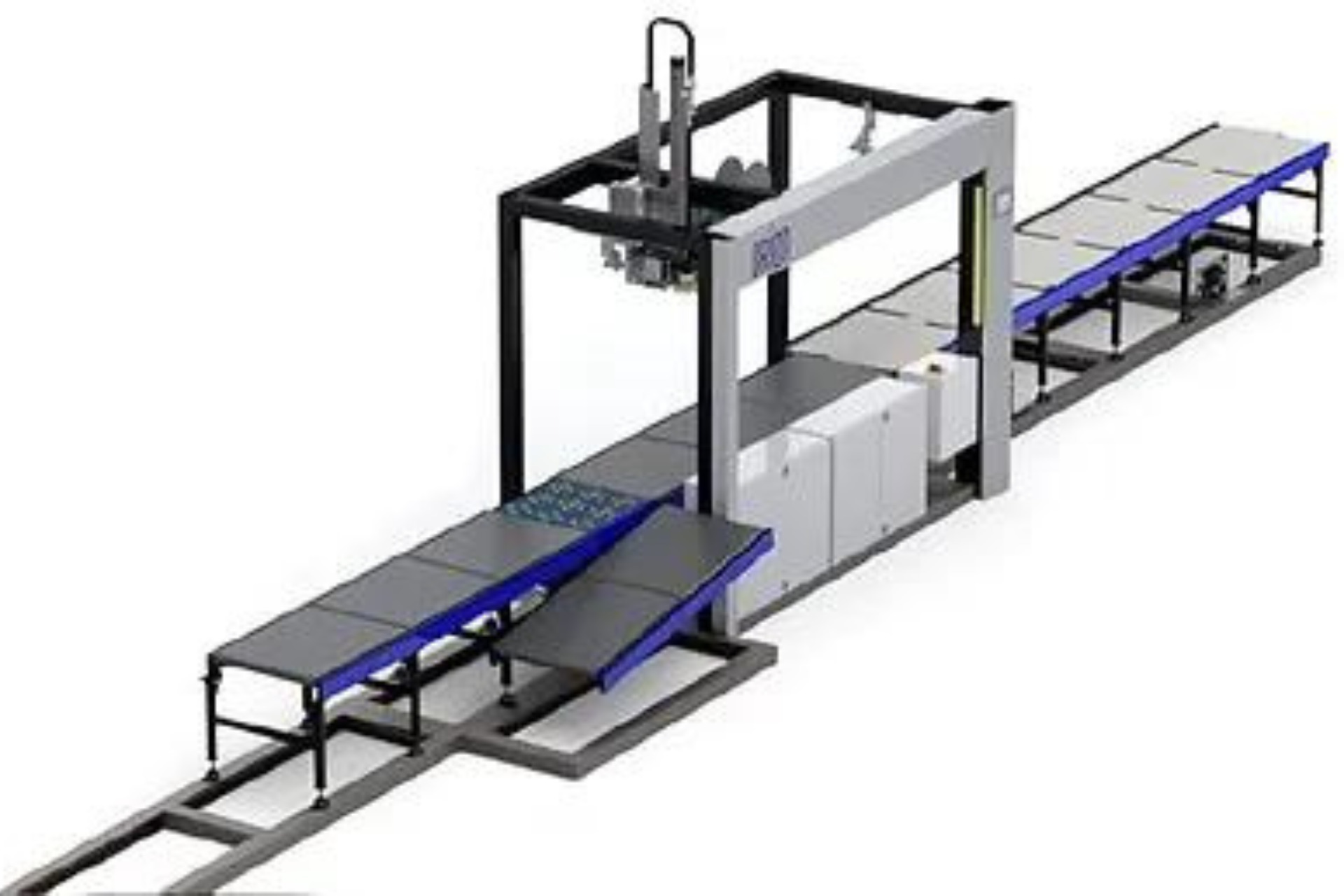

1. Automated Printing and Application

A robust print-apply labeling system should automate both the printing and application processes. This reduces the need for manual labor, minimizes human error, and speeds up the overall labeling process, resulting in increased productivity and efficiency.

2. Customizable Label Formats

Look for systems that can accommodate a variety of label formats, including barcodes, QR codes, and compliance labels. This flexibility allows businesses to meet diverse industry requirements without needing multiple labeling systems.

3. Integration Capabilities

Ensure that the labeling system can seamlessly integrate with existing production lines and technologies, such as barcode scanners or vision systems. This integration is crucial for maintaining a smooth workflow and enhancing overall operational efficiency.

4. Accurate Label Placement

Precision in label placement is vital to avoid mislabeling and reduce errors. Look for systems equipped with sensors or vision systems that ensure labels are applied accurately at the right time and position.

5. High-Quality Printing Technology

The system should utilize reliable printing technologies, such as thermal transfer or direct thermal printing, to produce high-quality labels with clear text and graphics. This ensures legibility and compliance with industry standards.

6. Scalability and Flexibility

Choose a system that can scale according to your production needs. A flexible design allows for easy modifications and upgrades as your business grows or changes, ensuring long-term usability.

7. User-Friendly Interface

A large touchscreen interface with intuitive navigation simplifies operation and troubleshooting. Systems that provide step-by-step instructions or troubleshooting tips can significantly reduce downtime and reliance on technical support.

8. Modular Design

Opt for a modular construction that allows for easy customization based on specific application requirements. This design makes it easier to replace parts or adapt the system for different labeling tasks without extensive downtime.

9. Durability and Maintenance Features

Consider systems built to withstand industrial environments with easy serviceability features. Look for options that minimize wear on critical components like print heads, which can enhance longevity and reduce maintenance costs.

10. Real-Time Monitoring and Feedback

Advanced systems may offer real-time monitoring capabilities to track performance metrics and provide immediate feedback on print jobs. This feature helps maintain quality control and ensures that any issues are addressed promptly.By focusing on these key features when selecting a print-apply labeling system, businesses can enhance their operational efficiency, reduce errors, and adapt to changing market demands effectively.