In the fast-paced world of manufacturing, efficiency and productivity are paramount. As industries continue to evolve, the need for advanced material handling solutions becomes increasingly critical. One such solution that has gained significant traction is the powered roller conveyor. These systems are transforming the way goods are moved within manufacturing plants, distribution centers, and warehouses. In this blog, we’ll explore the key benefits of powered roller conveyors, how they work, and why they are a game-changer for manufacturers.

What is a Powered Roller Conveyor?

Powered roller conveyors are systems that use motorized rollers to move products along a path. Unlike traditional conveyor systems that rely on gravity or manual effort, powered roller conveyors offer automated control, allowing for the smooth and consistent movement of goods. These systems are commonly used in a variety of industries, including automotive, food and beverage, logistics, and pharmaceuticals.

Key Benefits of Powered Roller Conveyors

-

Enhanced Efficiency

- Automated Operations: Powered roller conveyors reduce the need for manual handling, which can slow down processes and increase the risk of human error. Automated systems ensure that products move at a consistent speed, leading to smoother operations.

- High Throughput: With the ability to handle large volumes of goods quickly, powered roller conveyors can significantly increase the throughput of a facility. This is particularly beneficial in high-demand environments where time is of the essence.

-

Versatility and Flexibility

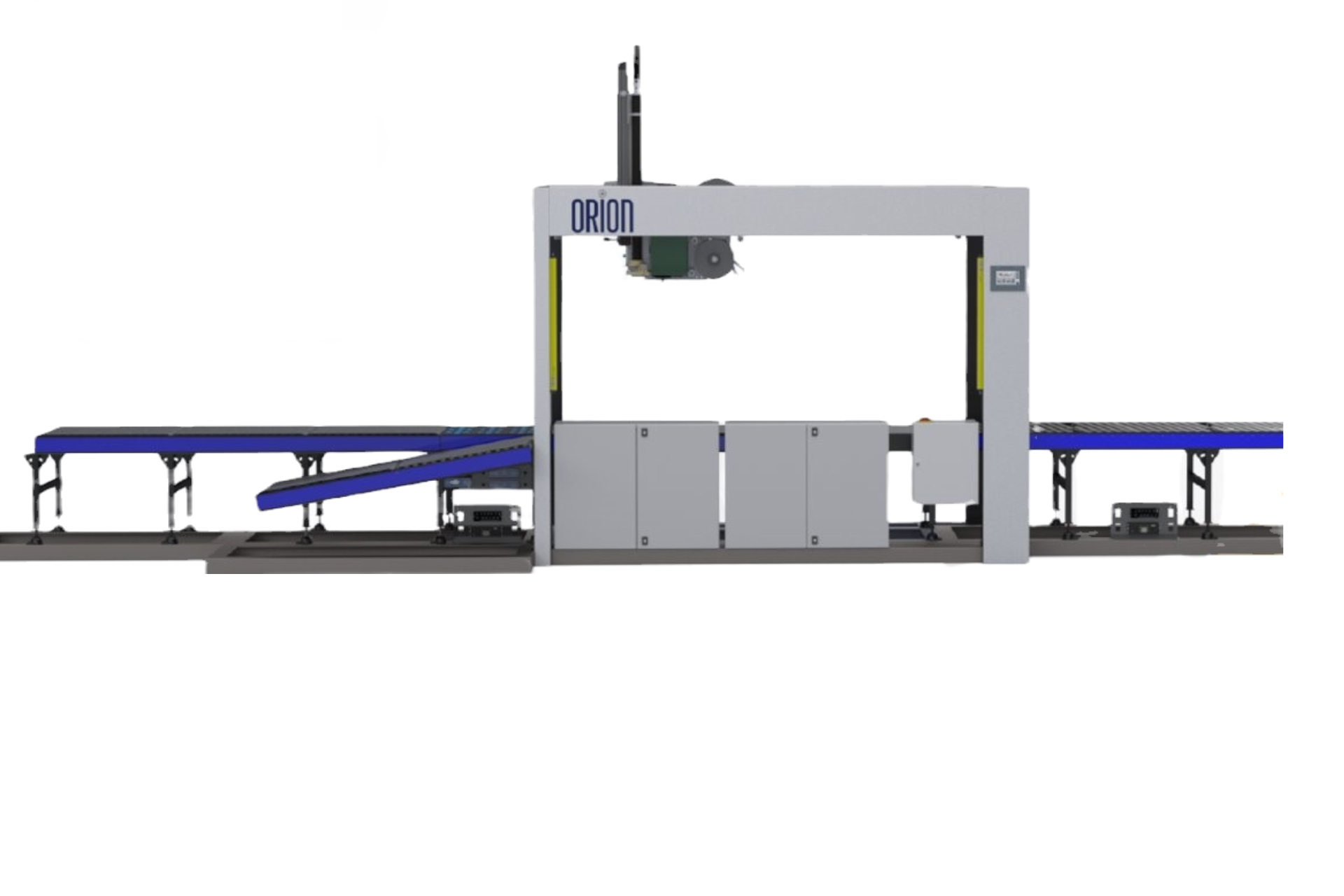

- Customizable Design: Powered roller conveyors can be tailored to meet the specific needs of a facility. Whether you need a straight path, curves, or inclines, these systems can be designed to fit any layout.

- Wide Range of Applications: From light to heavy-duty applications, powered roller conveyors are suitable for handling a variety of products, including boxes, pallets, and even fragile items.

-

Improved Safety

- Reduced Manual Handling: By automating the movement of goods, powered roller conveyors minimize the need for workers to lift and carry heavy items, reducing the risk of workplace injuries.

- Integrated Safety Features: Many powered roller conveyor systems come equipped with safety sensors and emergency stop features, ensuring that the system can be quickly halted in case of an obstruction or other hazards.

-

Cost-Effective Solution

- Lower Operational Costs: While the initial investment in powered roller conveyors may be higher than traditional systems, the long-term savings in labor, reduced product damage, and increased efficiency make them a cost-effective choice.

- Energy Efficiency: Many modern powered roller conveyors are designed to be energy-efficient, using motors that only operate when needed, further reducing operational costs.

How Powered Roller Conveyors Work

Powered roller conveyors consist of a series of motorized rollers that are connected by belts or chains. These rollers are typically powered by a central motor, which drives the rollers to move products along the conveyor path. The speed and direction of the conveyor can be easily controlled, allowing for precise movement of goods.

In more advanced systems, sensors can be integrated to detect the presence of products on the conveyor, allowing for automated sorting, routing, and accumulation. This level of automation can greatly enhance the overall efficiency of a manufacturing facility.

Why Powered Roller Conveyors are a Game-Changer

The adoption of powered roller conveyors can lead to transformative changes in a manufacturing environment. By automating the movement of goods, manufacturers can achieve higher levels of productivity, reduce operational costs, and improve workplace safety. Additionally, the versatility of these systems makes them suitable for a wide range of applications, from small-scale operations to large industrial plants.

In conclusion, powered roller conveyors are more than just a means of moving products—they are a vital component of a modern, efficient manufacturing process. As industries continue to evolve, the demand for advanced material handling solutions like powered roller conveyors is only set to increase. For manufacturers looking to stay ahead of the curve, investing in these systems is a smart choice.

Final Thoughts

If you’re considering upgrading your material handling processes, powered roller conveyors are an investment worth making. Their ability to improve efficiency, safety, and cost-effectiveness can provide a competitive edge in today’s fast-paced manufacturing landscape. Whether you’re a small business or a large industrial facility, powered roller conveyors can be customized to meet your specific needs, ensuring a seamless integration into your operations.