In today’s fast-paced logistics and supply chain industry, efficiency and accuracy are critical for businesses aiming to stay competitive. Warehouse automation services have emerged as a game-changer, helping companies streamline operations, reduce costs, and enhance overall productivity. In this blog, we explore the key benefits and applications of warehouse automation services.

What is Warehouse Automation?

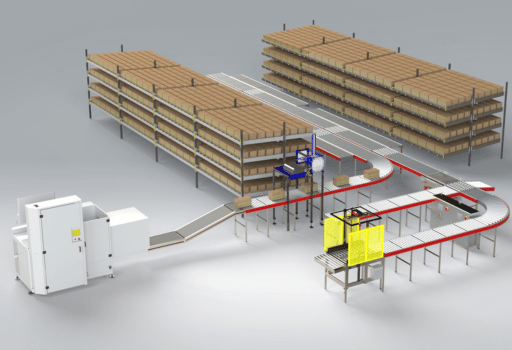

Warehouse automation involves the use of technology, robotics, and software systems to manage warehouse tasks with minimal human intervention. It includes automated storage and retrieval systems (AS/RS), robotic picking solutions, conveyor systems, and warehouse management software (WMS). These technologies work together to optimize material handling, inventory management, and order fulfillment.

Key Benefits of Warehouse Automation

1. Increased Efficiency and Productivity

Automated systems perform repetitive tasks at a much faster pace than human workers. With robots and AI-driven solutions handling order picking, packing, and sorting, warehouses can process higher volumes of goods efficiently, reducing labor-intensive operations.

2. Improved Accuracy and Reduced Errors

Automation significantly minimizes human errors in order fulfillment. AI-powered warehouse management systems ensure accurate picking and packing, reducing returns due to incorrect shipments. Barcode scanning and RFID tracking also enhance inventory accuracy.

3. Cost Savings and Labor Optimization

By reducing reliance on manual labor, businesses can lower operational costs. Automation helps redistribute human resources to more strategic roles while mitigating challenges related to labor shortages and workforce fatigue.

4. Better Space Utilization

Automated storage and retrieval systems enable warehouses to optimize vertical space, allowing for higher storage capacity within the same footprint. This maximizes storage efficiency and improves warehouse organization.

5. Enhanced Safety

Warehouse automation reduces the risk of workplace injuries by minimizing the need for employees to perform physically demanding or hazardous tasks. Autonomous robots and conveyor systems transport goods safely, preventing accidents associated with manual handling.

Popular Warehouse Automation Technologies

-

Autonomous Mobile Robots (AMRs): These self-navigating robots transport goods within the warehouse, improving picking and sorting efficiency.

-

Automated Guided Vehicles (AGVs): AGVs follow predefined paths to move inventory between locations.

-

Conveyor and Sortation Systems: Automated conveyor belts and sorting systems accelerate order processing and distribution.

-

Pick-to-Light and Put-to-Light Systems: These systems use LED lights to guide warehouse workers in picking and placing items, reducing errors and increasing speed.

-

AI-Powered Warehouse Management Systems (WMS): AI-driven software solutions optimize inventory tracking, demand forecasting, and workflow automation.

Future of Warehouse Automation

The future of warehouse automation is driven by AI, IoT, and machine learning. Smart warehouses are adopting predictive analytics, real-time tracking, and robotic process automation to improve decision-making and operational efficiency. As technology advances, fully autonomous warehouses are becoming a reality, revolutionizing supply chain logistics.

Conclusion

Warehouse automation services are transforming logistics by increasing efficiency, reducing costs, and enhancing accuracy. As businesses continue to invest in automation technologies, they will gain a competitive edge in an ever-evolving market. If you’re looking to optimize your warehouse operations, now is the time to explore automation solutions tailored to your business needs.

Ready to automate your warehouse? Contact us today to learn how our warehouse automation services can elevate your operations.