In the era of digital transformation, warehouses are no longer just storage spaces but intelligent hubs of logistics efficiency. Fully automated warehouse systems leverage cutting-edge technologies to enhance speed, accuracy, and cost-effectiveness. Let’s explore the key technologies driving warehouse automation.

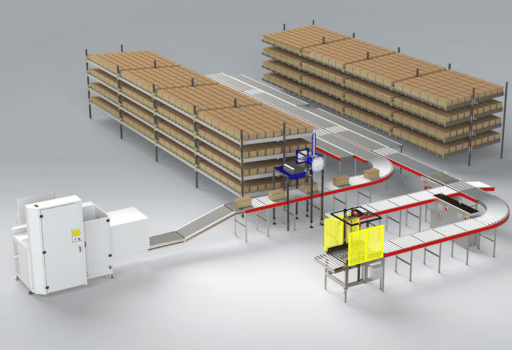

1. Automated Storage and Retrieval Systems (AS/RS)

AS/RS systems consist of robotic shuttles, cranes, and conveyors that automatically move goods between storage locations and retrieval points. These systems significantly reduce manual labor, increase storage density, and optimize order fulfillment speed.

2. Robotics and Autonomous Mobile Robots (AMRs)

Robotic solutions, including Automated Guided Vehicles (AGVs) and AMRs, help transport goods across warehouses without human intervention. AMRs, equipped with AI and sensors, dynamically navigate around obstacles and optimize routes in real time.

3. Internet of Things (IoT) and Smart Sensors

IoT-enabled sensors collect real-time data on inventory levels, environmental conditions, and equipment performance. These smart devices enhance predictive maintenance, prevent stockouts, and improve overall warehouse efficiency.

4. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML algorithms analyze historical and real-time data to optimize inventory management, predict demand, and enhance decision-making. AI-powered chatbots and virtual assistants also streamline warehouse communication and task management.

5. Warehouse Management Systems (WMS)

A robust WMS integrates with other automation technologies to provide end-to-end visibility of warehouse operations. It automates order processing, inventory tracking, and labor management to enhance productivity.

6. Radio Frequency Identification (RFID) and Barcode Scanning

RFID tags and barcode scanners facilitate seamless inventory tracking and identification. Unlike traditional barcode systems, RFID technology allows bulk scanning, reducing processing time and human errors.

7. Drones for Inventory Management

Drones equipped with RFID readers and cameras conduct fast and accurate inventory checks, eliminating the need for manual stock audits. They help in reducing operational downtime and improving inventory accuracy.

8. Cloud Computing and Big Data Analytics

Cloud-based warehouse management systems enable real-time data access from anywhere, facilitating better decision-making. Big Data analytics help identify trends, optimize warehouse layouts, and improve demand forecasting.

9. Automated Packing and Sorting Systems

Automated packaging machines and sorting systems streamline order processing by efficiently packing, labeling, and sorting items based on their destination. These systems reduce packaging waste and improve shipping accuracy.

10. 5G Connectivity for Real-Time Data Transfer

The implementation of 5G networks enhances communication between warehouse automation systems, ensuring faster and more reliable data exchange. This technology supports remote monitoring and real-time analytics.

Conclusion

Warehouse automation is revolutionizing the logistics industry by integrating advanced technologies that boost efficiency, reduce costs, and enhance accuracy. As businesses continue to adopt these innovations, the future of warehousing will be smarter, faster, and more autonomous. Investing in automation technologies today is key to staying competitive in the evolving supply chain landscape.