Warehouses are dynamic environments where efficiency and safety are critical. However, traditional warehouse operations often expose workers to significant risks, including heavy lifting, repetitive tasks, and potential collisions with equipment. Automation is revolutionizing these environments, not only boosting productivity but also enhancing safety and reducing workplace accidents. Here’s how automation transforms warehouse safety.

1. Minimizing Human Exposure to Hazardous Tasks

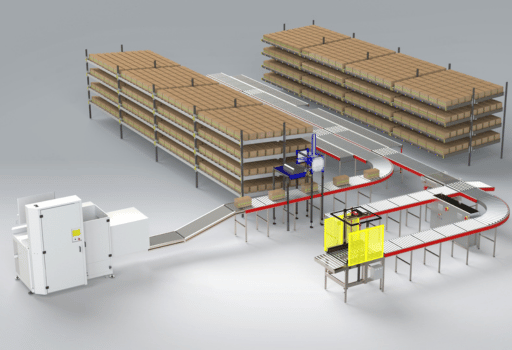

Automated systems like robotic arms and conveyor belts can handle repetitive and physically demanding tasks, such as heavy lifting, sorting, and palletizing. By reducing human involvement in these activities, warehouses can prevent injuries caused by overexertion and repetitive strain, which are among the most common workplace injuries.

2. Reducing Equipment-Related Accidents

Forklifts and other machinery are essential in warehouses, but they are also a leading cause of workplace accidents. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) reduce the need for human-operated equipment. These machines are equipped with advanced sensors and navigation systems to avoid collisions, enhancing overall safety.

3. Enhancing Precision and Predictability

Human error is a significant factor in workplace accidents. Automation reduces the risk of mistakes by performing tasks with precision and consistency. For example, automated inventory management systems can accurately track and move items, minimizing the likelihood of errors that could lead to accidents, such as improperly stacked goods.

4. Improving Ergonomics

Ergonomic injuries, like back strains and musculoskeletal disorders, are common in warehouses. Automation eliminates the need for workers to perform awkward movements or handle heavy loads, promoting a safer and healthier work environment.

5. Real-Time Monitoring and Risk Detection

Automation systems often include advanced monitoring and analytics tools. These tools can detect potential hazards, such as equipment malfunctions or blocked pathways, in real time. By alerting workers and managers immediately, automation helps prevent accidents before they occur.

6. Ensuring Compliance with Safety Standards

Automated systems are designed to operate within predefined safety parameters, ensuring consistent adherence to workplace safety regulations. This reduces the risk of violations and creates a safer environment for employees.

7. Training Workers for Safer Interactions

Automation doesn’t eliminate the need for human workers; instead, it changes their roles. Employees are trained to operate and interact with automated systems, equipping them with the skills to work safely alongside technology. This reduces the risk of accidents caused by a lack of familiarity with equipment.

8. Emergency Response and Contingency Management

Some automated systems are equipped with emergency shut-off features or can execute predefined safety protocols during crises. For instance, fire-detection automation can alert the entire warehouse while triggering suppression systems, mitigating risks to employees.

The Future of Warehouse Safety

As automation continues to evolve, its role in enhancing warehouse safety will only grow. Innovations like AI-powered robots, wearable safety devices, and machine learning algorithms promise to create safer and more efficient warehouses.

By reducing human exposure to hazards, improving precision, and enabling proactive risk management, automation is a game-changer for workplace safety. Businesses that adopt these technologies not only protect their employees but also improve operational efficiency—a win-win scenario for everyone involved.

Conclusion

Investing in automation is an investment in safety, productivity, and long-term success. With fewer accidents, healthier workers, and seamless operations, automated warehouses set the standard for modern industry practices.

If your business is considering implementing automation, now is the time to explore the possibilities. The safety of your team—and the future of your operations—depend on it