Belt conveyors have long been a cornerstone of material handling systems across various industries. However, recent advancements in technology are revolutionizing their design and functionality, making them more efficient, flexible, and user-friendly. This blog explores some of the latest innovations in belt conveyor technology, highlighting how they can enhance operational efficiency and adaptability in today's fast-paced environments.

Modular Conveyor Systems: The Rise of ModFlex Conveyors

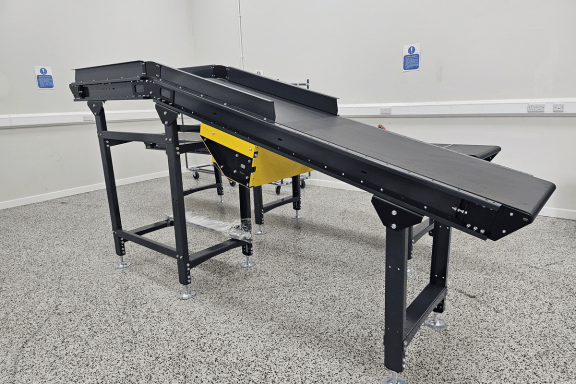

One of the most significant advancements in belt conveyor technology is the introduction of modular conveyor systems, such as the ModFlex Conveyors from Orion. These conveyors feature a modular design that allows for easy configuration and reconfiguration, enabling businesses to adapt their material handling systems to changing production layouts and requirements. This flexibility is crucial for companies looking to optimize their operations without incurring high costs associated with traditional conveyor modifications.

Enhanced Performance Features

Modern belt conveyors now incorporate advanced features that streamline operations. For instance, adjustable speed controls allow for precise management of product flow, optimizing throughput and minimizing bottlenecks. Additionally, integrated sensors for product detection enable automated sorting and routing, significantly reducing the need for manual intervention and the potential for errors.

Customization and Scalability

Today's belt conveyors are designed with customization in mind. Manufacturers now offer solutions that can be tailored to specific operational needs, including customizable roller pitches, lengths, and widths. This adaptability ensures that businesses can implement conveyor systems that perfectly fit their unique processes, whether they are handling lightweight items or heavier loads.

Energy Efficiency and Sustainability

With increasing focus on sustainability, advancements in belt conveyor technology also include energy-efficient designs. Many modern systems utilize drum motors and central drive options that reduce energy consumption while maintaining high performance. This not only lowers operational costs but also supports corporate sustainability initiatives.

Integration with Automation Technologies

The integration of belt conveyors with automation technologies, such as robotic arms and barcode scanners, is another notable trend. This synergy enhances material handling efficiency by allowing for seamless operation across different systems. By automating various processes, businesses can achieve higher productivity levels and reduce labor costs.

Conclusion

The advancements in belt conveyor technology are transforming how businesses approach material handling. With features like modular designs, enhanced performance capabilities, and integration with automation, modern belt conveyors are more adaptable and efficient than ever before. Companies looking to improve their operations should consider investing in these innovative systems to stay competitive in a rapidly evolving marketplace.For more information on cutting-edge conveyor solutions, consider exploring the offerings from manufacturers like Orion, who are at the forefront of these technological advancements. Embracing these innovations can lead to significant improvements in productivity and operational efficiency